Converting to plastics

Plastic as a construction material

Technical plastics are now much more robust and advanced. There are many possibilities for using them, even in more demanding functions.

Plastic can be used as a construction material in a variety of applications across diverse industries. It is often used to advantage instead of such materials as metal, steel and wood.

Plastic allows considerable freedom for designing parts that come in at an affordable price per item. This means significant savings can be made. The switch from other materials to plastic is worthwhile on a number of levels.

In this brochure you will find inspiration for converting your existing parts and machine parts.

Why you should consider technical plastics

There are many types of technical plastic, which is also known as construction plastic. Each one has its particular advantages which mark it out from other materials.

Below you will find some of the indicated advantages from which you will enjoy benefits as against other materials.

Plastic has a lower bulk density

One of the most evident advantages of plastic over metal is its bulk density.

Some technical and high-performance plastics which can be deployed instead of metal weigh up to eight times less than steel, for example. So plastic machine parts simply weigh less.

This means that your plastic products will be lighter, resulting in a lower transport weight.

See the below table for a selection of technical plastics and their bulk densities.

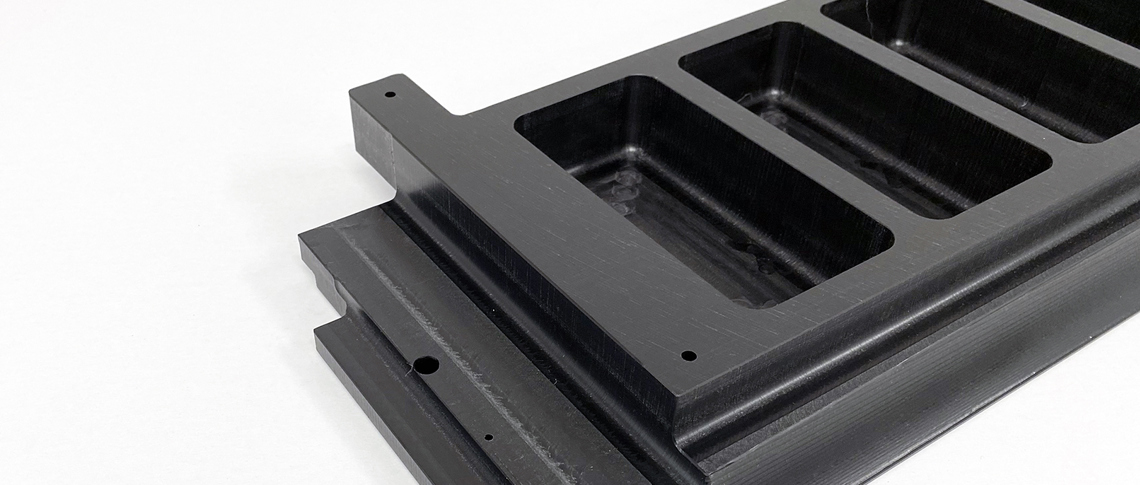

Consolidate several parts into a single part

When you switch to plastic, several functions can often be integrated into a single new plastic part.

For example, a machine part that before conversion consisted of several wooden or steel parts can be combined into a single plastic part.

The integration of single components can simplify the manufacturing process, often reducing production costs.

See an example of combining several parts in this customer case study.

Minimise or remove the need for lubricants

When using plastic, there is little need for oil or other lubricants.

This is true even where the plastic is exposed to mechanical strains and must be able to glide without hindrance.

Some types of plastic, such as PTFE, are so low in friction themselves that there is no need for lubricants.

The friction properties of plastic may be so good that plastic parts used without lubricants can have better friction properties than metal parts on which lubricants have been applied.

Even though plastic has excellent friction properties in itself, there are plastics with additives that increase the friction properties even more.

A good example of this is polyamide PA 6 (nylon) with added MOS2 (molybdenum disulphide) and oil. If a machine part made from this material is exposed to sufficiently high pressure, the oil will migrate to the outer face of the material, thus increasing friction.

Your plastic parts are also manufactured without lubricants or cooling liquids. This is why your plastic parts are completely clean when you take delivery of them.

Plastic works well across all environments

The various construction plastics often have several properties that make them suitable across environments.

Shims in a machine that will produce or handle food must be able to cope with chemicals, because of the need for intensive cleaning. They must also be food-approved as the machine will be in contact with foodstuffs.

If the shim is made in steel, it has to be lacquered in order for it to cope with chemicals; it must also be stainless, so that it is allowed to be in contact with foods. Steel therefore requires two different materials or surface treatments.

But the same shim in PEHD plastic can be exposed to both chemicals and foods.

Plastic is steady and unchanging

In contrast to surface-treated/coated materials, plastic is a constant material throughout. The composition of plastic is the same on the surface as in the core of the material.

This is another reason why there is no need for surface treatment of your plastic parts. Surface treatments such as galvanisation and varnishing are superfluous.

Another advantage is the way plastic retains its surfaces and consistency – even though it also glides. There is no risk therefore that a surface will wear down, or suffer degradation over time.

Plastic has increased durability against wear

Staying on the subject of wear, we encounter yet another advantage of plastic that is worth highlighting. In contrast to its conventional image, plastic is extremely hard-wearing.

Technical plastics such as polyamide (nylon) and PEHD, for example, perform very well in abrasive environments.

Tests (ISO 15527) show that polyamide, PEHD 1000 and PEHD 2000, for example, withstand tests with sand better than steel or aluminium.

See the table below for wear statistics for various plastics and metal.

Plastic absorbs less moisture than wood

Depending on the environment your machine part will be exposed to, the fact that it does not absorb moisture may be in your favour.

In particular, PEHD (polyethylene) has a very low moisture uptake.

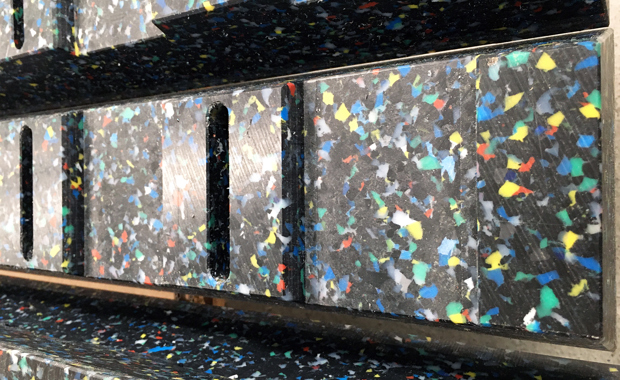

Plastic comes in many colours

Several technical plastics are available in different colours and can be used in various systems. For example, a vibrant yellow or red can be a warning.

It is also possible to order the same colours in different kinds of plastic. For example, you can have exactly the same blue in PEHD and POM.

The colour-fast nature of the dye is because it is coloured throughout. If the plastic wears, the colour will not be lost or diminish as much as if the colour were merely an external coating.

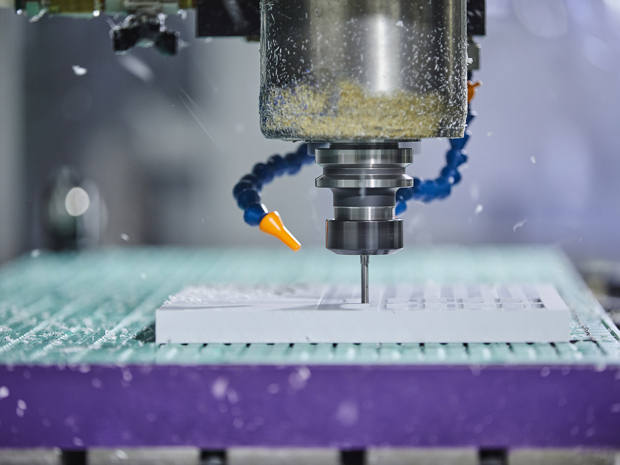

Plastic is quick to process

It is faster to process plastic than metal, for example. Plastic is quite simply softer and therefore travels on machinery faster.

Moreover, parts made of plastic need no further finishing such as surface treatments; you save at least one process step.

In short, conversion to plastic means financial savings!

Increased durability of parts, quicker production, omission of surface treatments and integration of components mean that choosing plastic is a way to save money.

Remember: it doesn't need to be complicated. Switching even a simple part can mean a significant cost-efficiency.

When is it not advisable to choose plastic?

There can be certain mechanical requirements that plastic is not cut out for.

Long parts in plastic are not advisable, such as trusses or rafters of several metres that are under constant pressure. Plastic would simply bend under such conditions.

But where such mechanical demands do not exist, plastic is a good alternative; and it is ideally suited to a host of machine parts, belts, spacers and more besides.

We hope we have stirred your curiosity about the way plastic can make a difference to your production method or your product.

If so, please feel free to contact us.

Reconstruction of parts in plastic

If you are changing from metal – or indeed another material – to plastic, you should be aware that it may not be possible to transfer the previous design to that of a new construction for plastic production. The part may need to be reconstrued to avoid deficiencies in strength or surface properties.

In the process of redesigning, one must carefully consider the purpose of the item as well as the environment it will be subjected to. Factors include:

- Strength

- Rigidity

- Thermal expansion

- Temperature resistance

- Tolerances

- Regulatory requirements (UL 94/Atex antistatic properties and similar)

- Requirements for protective screening

- Product lifetime

The most important thing in this process is to clarify end use: knowing details can be important when it comes to making the correct choice.

We will provide guidance

At Induflex, we are well versed in guiding customers through the processes of switching from steel to plastic, covering all aspects from the reconstruction of existing products to the manufacture of new ones in a different material.

We are able to advise you, taking into account your needs and production methods to find the best possible type of plastic and construction.

We are happy to conduct a review of your production system, completely without obligation. It could perhaps reveal where plastics might afford both economic and environmental gains.

Contact us to find out more.

Questions and answers about converting to plastics

There is a wealth of products that can switch to plastic production. We have considerable experience of converting various machine parts such as toothed wheels, screws, sub-assembles and profiles.

Many types of metal, steel and wood.

This depends greatly on the environment and the machinery, as well as the type of plastic.

If you have an item, you are considering reformulating, we will be happy to provide a precise evaluation of durability, should you want to produce it in plastic – and there is no obligation.