Our Approach to

the Environment

and Sustainability

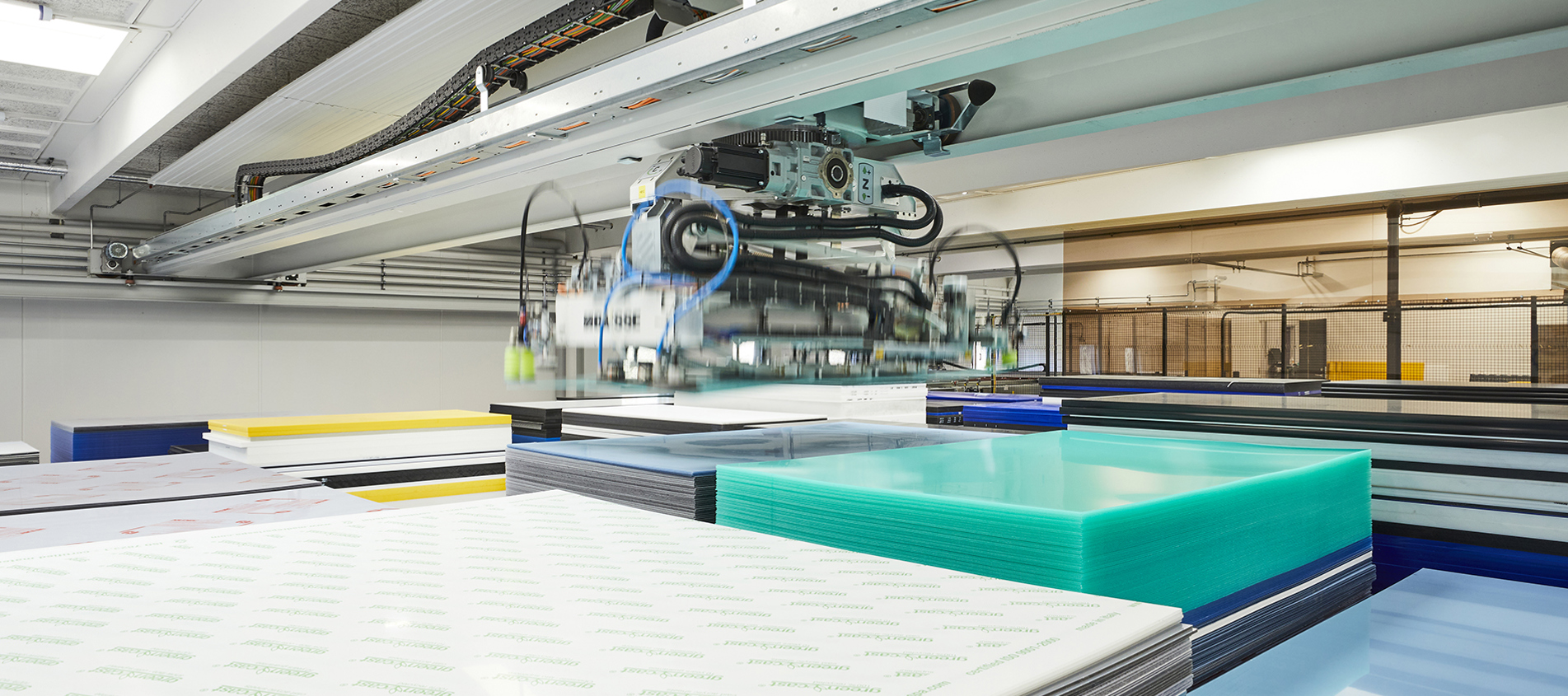

Without plastic, the world would be in a difficult place. Plastic makes a huge difference in people's lives and helps ensure a more convenient, efficient, and better everyday experience. Many people view plastic with skepticism and fail to recognize its sustainable dimension.

Using alternative materials would require significantly more resources, resulting in much higher CO2 emissions. This would lead to less comfort, more food waste, poorer hygiene, more expensive goods, and a huge setback for humanity. Plastic is a great idea, and we are committed to making it even better.

An environmental benefits

of converting to plastic

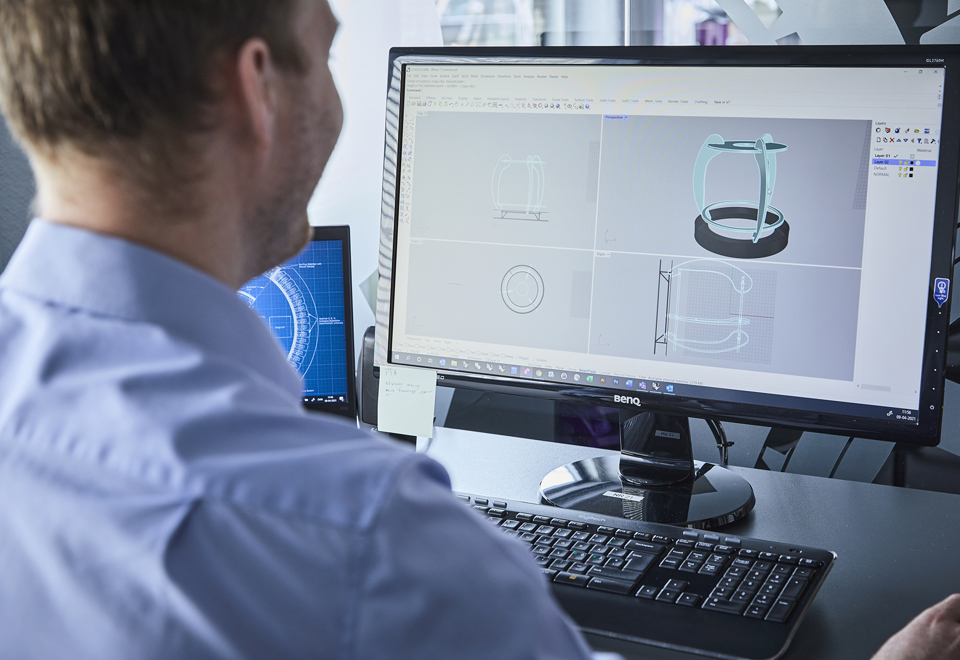

It is often overlooked that there can be a sustainable aspect to converting, for example, machine parts from another material such as steel or wood to plastic. Nonetheless, there are often advantages to such a conversion. If you are curious about whether plastic could make a difference in your company, we are happy to provide guidance.