CNC turning of many types of technical plastics

We turn your machine parts in plastics

By turning plastic, we can produce custom blanks, working from STEP files and drawings -

exactly according to your requirements.

Our CNC turning lathes allow us to make various machine components such as toothed wheels, flanges, rolls and drive arms.

Our machining workshop has capacity for both small and large production, as well as prototype production.

CNC turning of plastics

Processing plastics is a business that makes unique demands of the tools and methods employed.

All our CNC lathes are specially adapted to turn plastic - and we only work with plastics.

When you order a turned plastic component from us, we will help you with the design and choice of materials to ensure that your product will live up to your requirements.

In the video below you can see how we make turned machine parts for one of our clients.

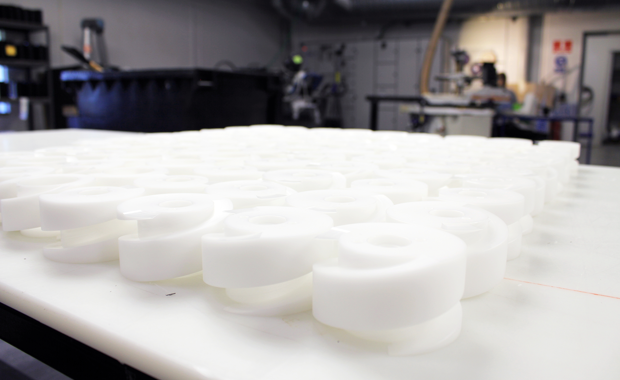

Pure blanks

At Induflex, our production is pure and air-cooled. This means that the product will be free of residues and ready to use without prior cleaning.

Trained specialists

We are happy to encounter challenges! When you order a turned product from Induflex, it will be made by professionals whose specialisation is processing plastics.

Your product is in safe hands, from the programming of the lathe to the manufacture of the finished item.

A uniform high-quality finished product is assured – even with the more challenging of tasks.

Efficient CNC turning of your parts

We have capacity, from single pieces right up to serial production; we will always employ the most efficient process to make your product.

We are continually aware of and ready to develop new production methods, as well as to optimise our current processes. We will be happy to fine-tune your design and machine tools to comply with your requirements. You will receive the best quality, at the right price.

Do you have a question about parts or do you want to know more?

Get in touch with us and we will help you.

Questions and answers about CNC turning

We turn blanks in a wide range of sizes from a few centimetres, to several metres. Contact us for more information about dimensions.

We turn blanks in various types of plastic like acrylic (PMMA), PEHD, POM, PEEK and many more.

The greatest challenge in machining plastic is tension, which inevitably arises in the material.

To avoid this, tolerances must take account of expansion factors in the structure as well as water absorption. If this is not properly computed, the tensions make the plastic burst, crack or crumble.

When you order a plastic product from us, we assist you in the construction and choice of material, so that the end product will live up to your expectations.

We have great experience processing plastics and avoiding or minimizing these tensions, making sure you are in good hands when ordering turned plastic components from us.