Technical plastics refer to a group of plastic types commonly used for parts and constructions that require higher technical and chemical properties. These may include wear resistance, tensile strength, heat and chemical resistance, as well as flame-retardant properties.

Technical plastics are typically thermoplastics, which can be melted and reshaped repeatedly.

High-performance plastics build upon these properties. Materials like PEEK, PTFE, and PVDF are among the best polymers, boasting outstanding characteristics such as low friction, weight reduction, permanent operating temperatures exceeding 150 °C, and enhanced chemical resistance.

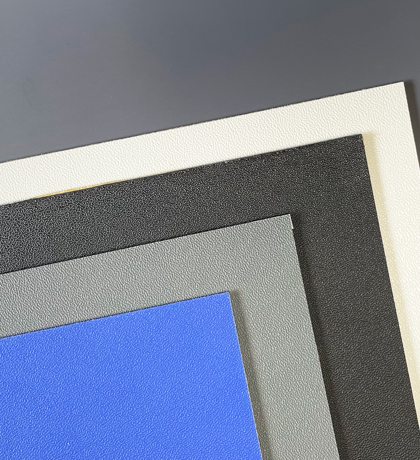

In the image beside, you will find a categorization of the various types of plastics.