Acrylonitrile butadiene styrene (ABS)

What is ABS?

ABS is produced by combining the three substances acrylonitrile, butadiene and styrene - hence the abbreviation ABS.

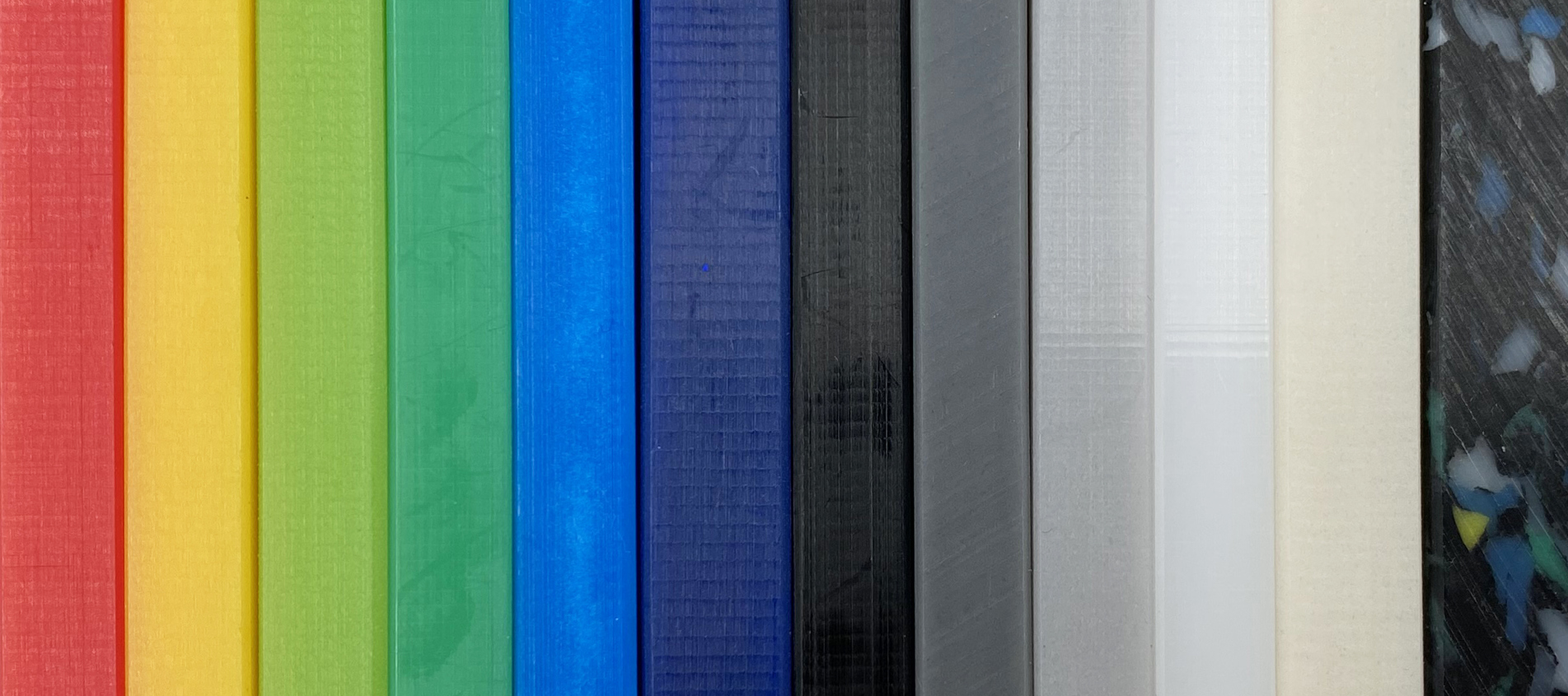

ABS plastic can be supplied in sheets and rods with many different surface options (grains) and several different colours such as blue, red, green and yellow.

At Induflex, we can make your ABS products in different colours and thicknesses.

We carry as standard thicknesses of 1.5 mm, 1250 x 2500 mm in grey, blue and white and 3 mm, 1300 x 2800 mm in black. We will be happy to order other colours and sizes for delivery to you.

ABS also goes by the trade name TECARAN® ABS.

The characteristics and applications of ABS

ABS plastic is known for its extreme rigidity, toughness and wear-resistance, even at low temperatures.

The material has good resistance to chemicals and low water absorption. It is also electrically insulating.

Therefore ABS is often used in casing such as:

- Domestic appliances

- Phones

- Computers

- Printers

ABS with a grain side

ABS is also highly impact-resistant and can be supplied in several types of grainy surface. ABS parts are therefore often ‘nicer’ than the surface of PEHD 300.

The grain also ensures that the ABS part will not look scratched after a short time in use.

ABS can therefore be used to advantage in products where appearance and surface are design requirements – in combination with the aforementioned properties, such as high wear resistance.

ABS is therefore often used in products such as:

- Screens

- Vacuum-formed parts

- Covers

- Equipment for cars

Note that ABS may be affected by UV and is therefore not suited to outdoor applications.

It is also worth noting that ABS is not resistant to strong solvents.

Food-approved ABS

ABS is not FCM-approved.

Alternatives to ABS Plastic

Depending on the end application and requirements, PVC, polypropylene, polystyrene, polycarbonate or acrylic can be good alternatives to ABS. Are you unsure about which plastic that will meet your requirements? We will gladly guide you.

Processing ABS

We perform heat bending, CNC turning and milling of your ABS products. We can also cut ABS with a knife on our cutting plotter. If we have your preferred ABS in stock, we can cut your parts in five days.

To learn more about ABS, please consult our plastics product range table.

If you have any questions about ABS or its processing, please do not hesitate to contact us.