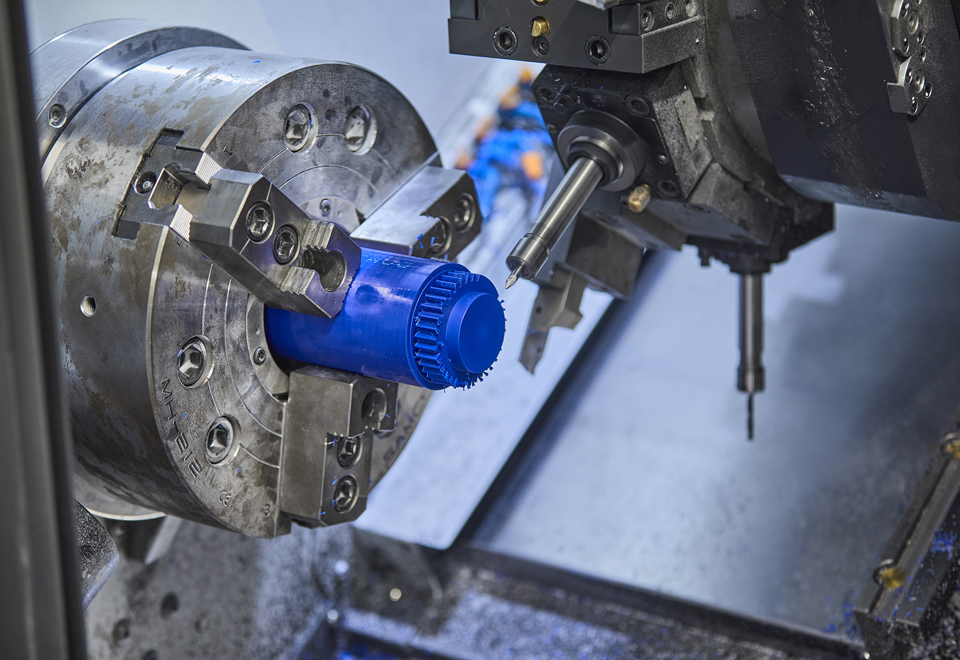

Plastic machine parts for the

food industry and food processing sector

It is difficult to imagine the production and sale of food without the use of plastics. Plastics are used, among other things, for manufacturing mechanical components, wear parts and protective guards in the production equipment used within the food industry.

We have extensive capacity and expertise in processing plastic parts and machine components for use in food-processing machinery and food production facilities.

In most cases, we can manufacture you machine parts in food-approved plastics within 7-14 working days.

Plastics for the

food industry

When it comes to processing components in food-processing equipment, choosing the right plastic is crucial. Selecting the correct material for the specific task is essential - and the right type of plastic can also extend maintenance intervals due to reduced wear.

Different plastic types offer a wide range of properties that can be highly advantageous in the food industry and food production, such as.

- PEHD500/PEHD1000 is excellent for wear involving water and sand. Possibly the most commonly used plastics in the food industry - thanks in large part to their strong material characteristics.

- Polyamide (nylon) is tough and durable, capable of withstanding heavy loads and pressure.

- POM offers short processing times in production and can tolerate high loads.

- PTFE (Teflon®) is a relatively soft plastic with extremely low friction.

- PEEK features strong mechanical properties and excellent thermal stability - able to withstand temperatures of up to 250 °C.

- PVDF is particularly suitable for environments with strict hygiene requirements, such as the pharmaceutical or dairy industries.