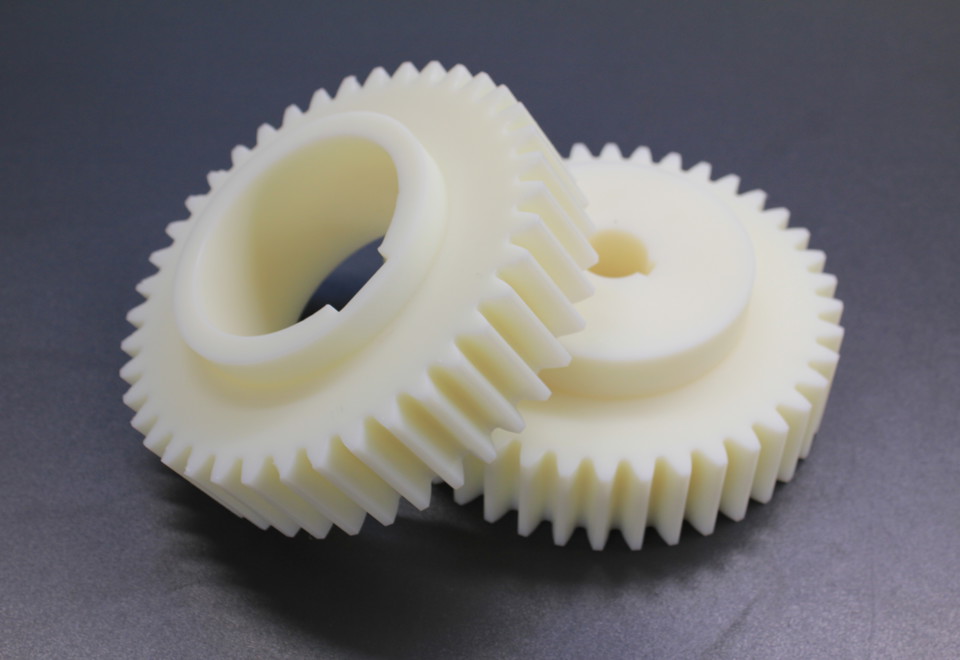

Plastic gears are ideal for a wide range of industrial machines. They are an excellent alternative to metal when low friction, corrosion resistance and minimal maintenance are required.

This is also because metal versions can seize, whereas plastic behaves differently. By adding specific additives, the material properties can be improved. One such additive is oil, which migrates to the edges of the gear teeth, allowing the components to release itself and providing self-lubricating properties. However, this does not remove the FCM (food-contact) approval.

In this way, plastic components can solve many of the issues typically encountered with metal gears.