12.04.24

From traditional materials

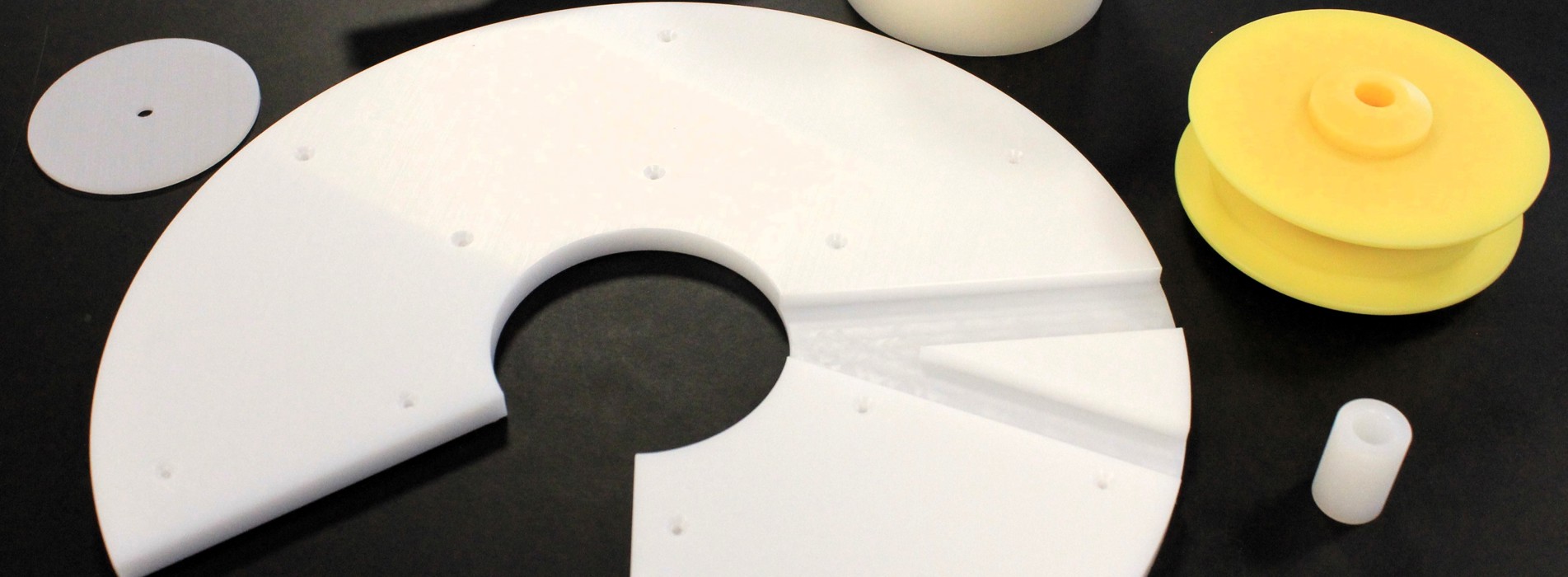

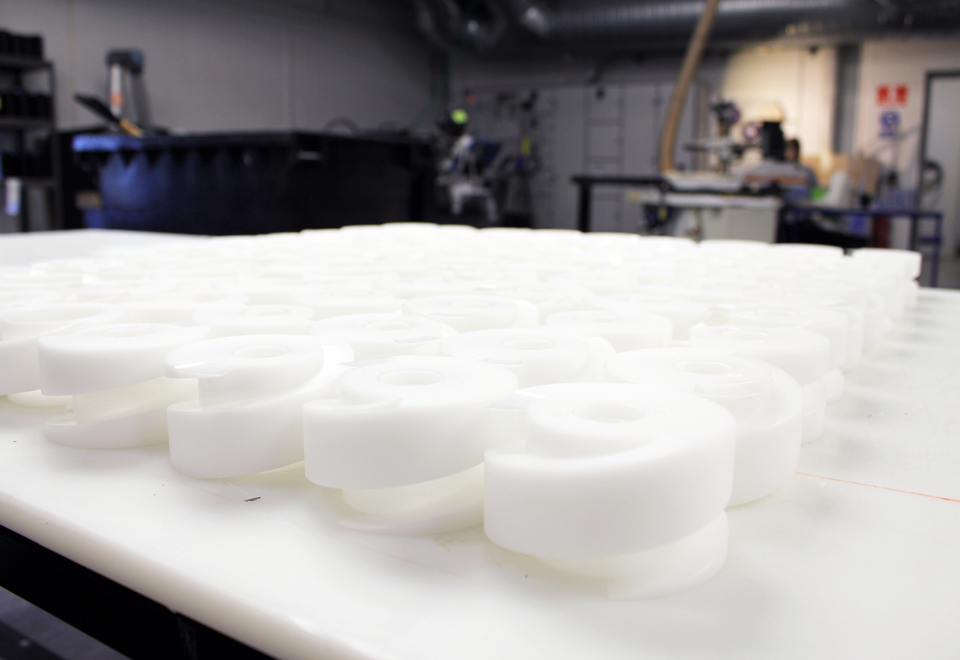

to new possibilities with plastics

Traditionally, metal and steel have been preferred materials for industrial components. However, today engineering plastics are gaining ground as an attractive alternative. Engineering plastics, also known as structural plastics, offer a range of advantages that make them an ideal choice, even for the most demanding tasks.

Engineering plastics represent a group of plastic materials specifically designed to meet the technical and chemical requirements of various applications. Here are five good reasons why it can be beneficial to switch from metal and steel to engineering plastics.

Contact us today

Bárður Jónsson Stórá

Sales Coordinator

Tina Heslop Christensen

Sales and Project Coordinator