Spørgsmål og svar

-

By sending us a STEP file or PDF with your drawings, we can quickly assist you in determining whether polycarbonate is the right choice for your project.

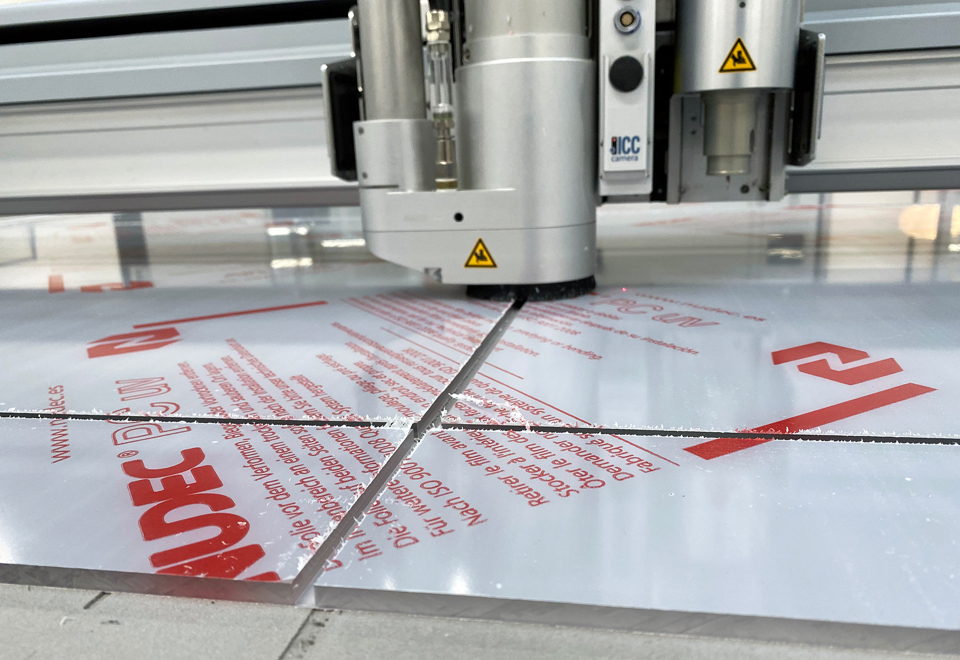

We can also identify the best machining method for your item.

-

At Induflex, we can achieve very tight tolerances in plastic.

When you order a plastic part from us, it will comply with Danish Standard ISO 2768-1 (medium) by default. We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you wish.

-

PC is not FDA-approved as standard, but we can order fully documented FDA-approved polycarbonate for you if your project requires it.

-

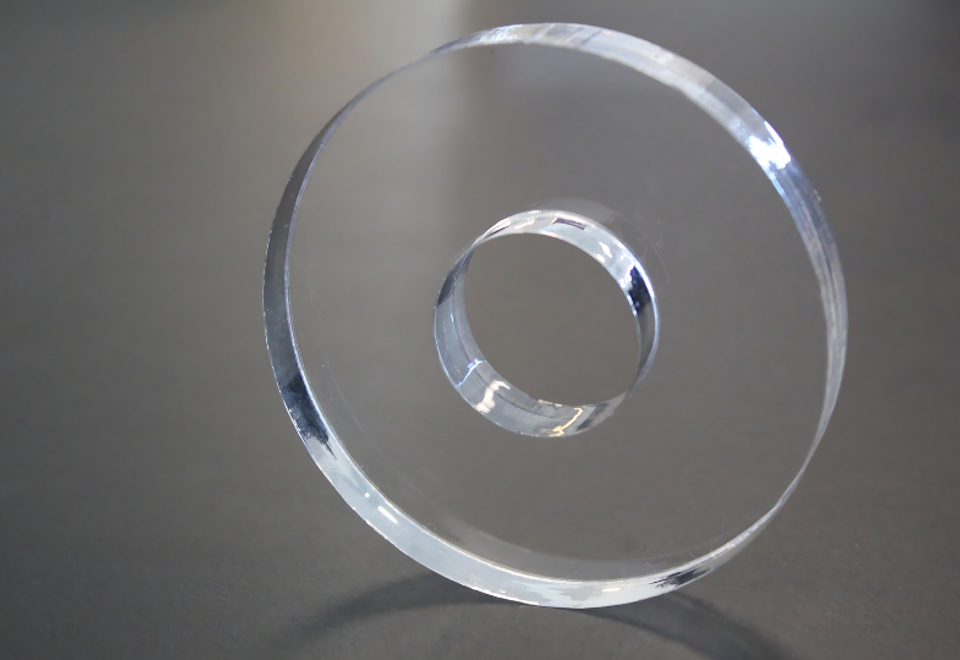

As polycarbonate is a moderately rigid material, it is notch-sensitive. Although PC is known for its impact resistance, cracks or fractures can increase the risk of weaknesses in both the material and the final component.

To achieve maximum durability, sharp corners should be avoided in the design.

Some materials can be ordered with additives that strengthen the construction. Contact us for more information.