Spørgsmål og svar

-

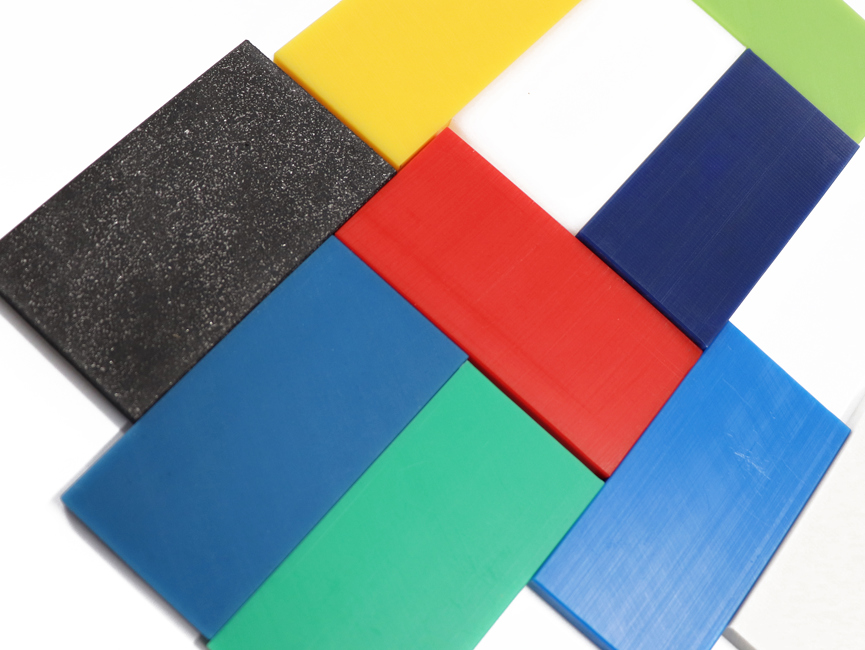

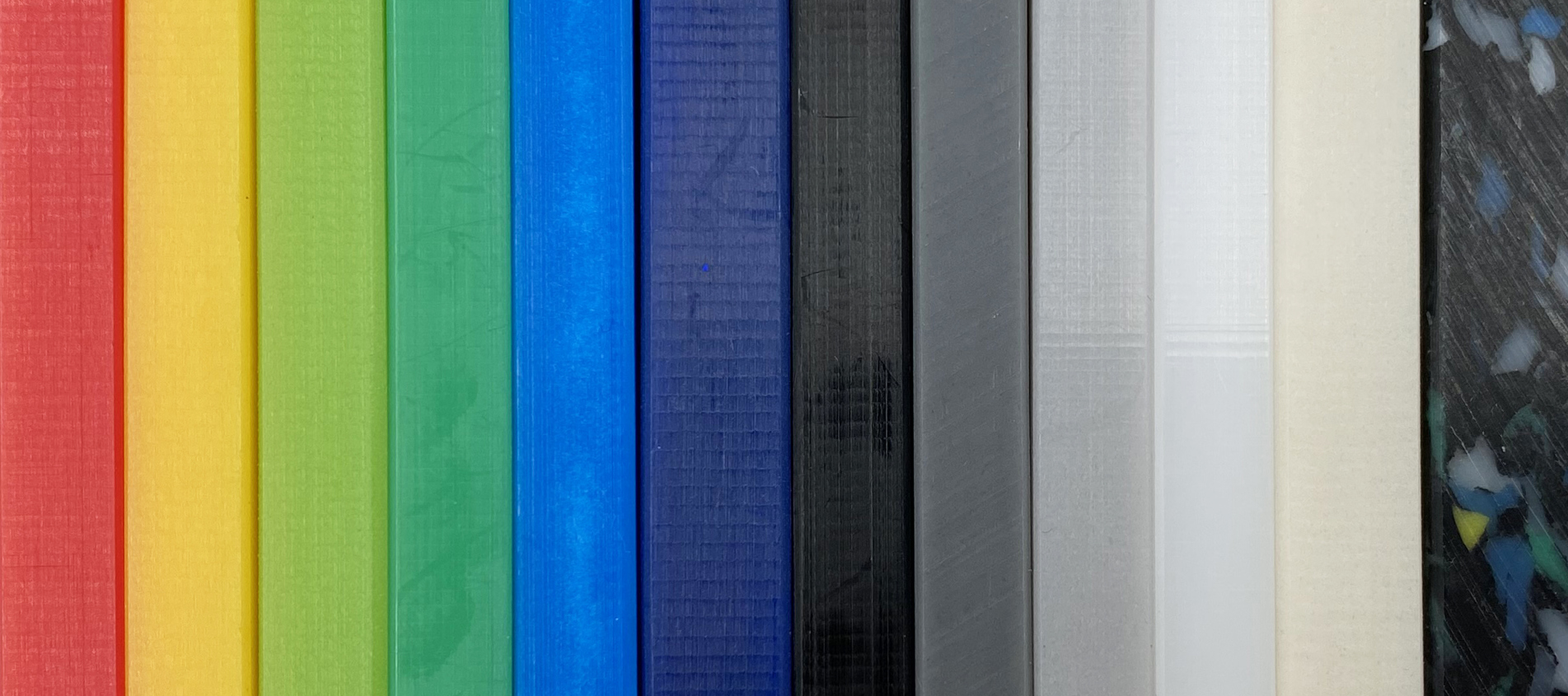

We keep PEHD in stock in blue, natural, and black as our standard colours. In addition, we often have other colours such as yellow, green, and red available – please feel free to contact us to enquire about current availability.

Our stock includes PEHD 300, PEHD 500, and PEHD 1000.

If you require a specific colour or grade, we are of course happy to source it for you. Contact us for more information.

-

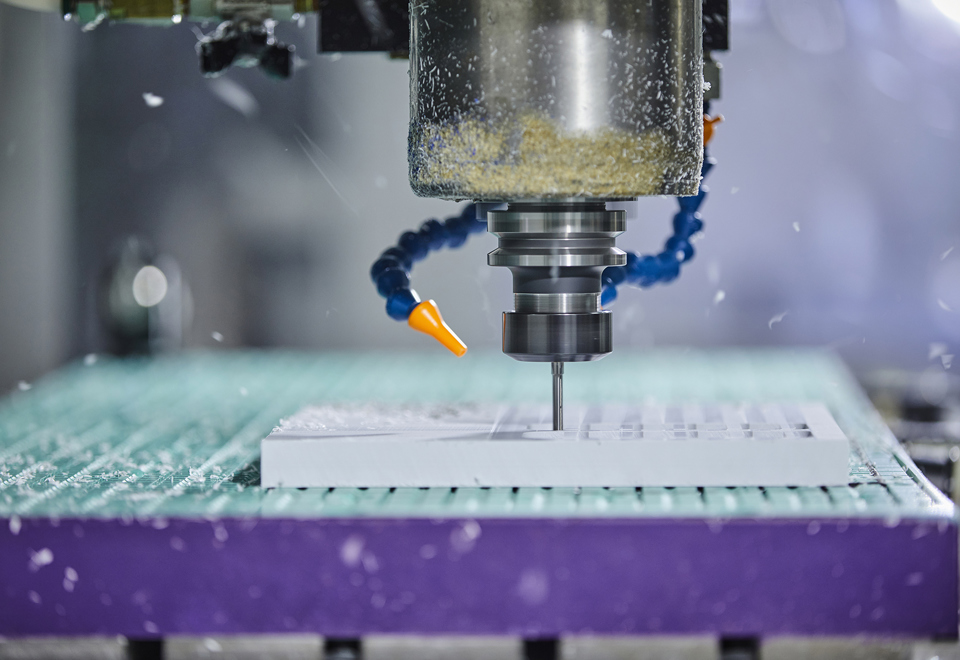

At Induflex, we can achieve even very tight tolerances in plastic.

When you order a plastic part from us, it will, as standard, comply with Danish Standard ISO 2768-1 (medium). We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you prefer.

-

PEHD is not notch‑sensitive. It is a relatively flexible material with good ability to absorb energy without developing weaknesses.

It is therefore suitable for applications where the material is subjected to impact or shock.

However, sharp corners should still be avoided to ensure optimal durability.

Some materials can be ordered with additives that will strengthen the construction. Please contact us for more information.

-

By sending us a STEP file or PDF with your drawings, we can quickly assist in determining whether POM is the right choice for your project.

We can also identify which machining method is best suited for your item.

-

PEHD is an FCM-approved technical plastic, making it suitable for items that come into direct contact with food, such as components for food processing machinery.

-

PEHD, along with many other types of plastic, can be supplemented with additives to better tailor the material to the specific application.

However, this does require a longer delivery time, as it is typically a special-grade material.

There are more than 500 possible modifications.

Please note: all FKM approval becomes invalid when you modify virgin materials.