Machine parts for

the Wind Industry

In the wind energy industry, plastic components play a critical role in improving turbine efficiency, reducing weight and improving durability. From wind turbine blades to control systems, plastics are used in many applications that contribute to the overall performance of wind farms.

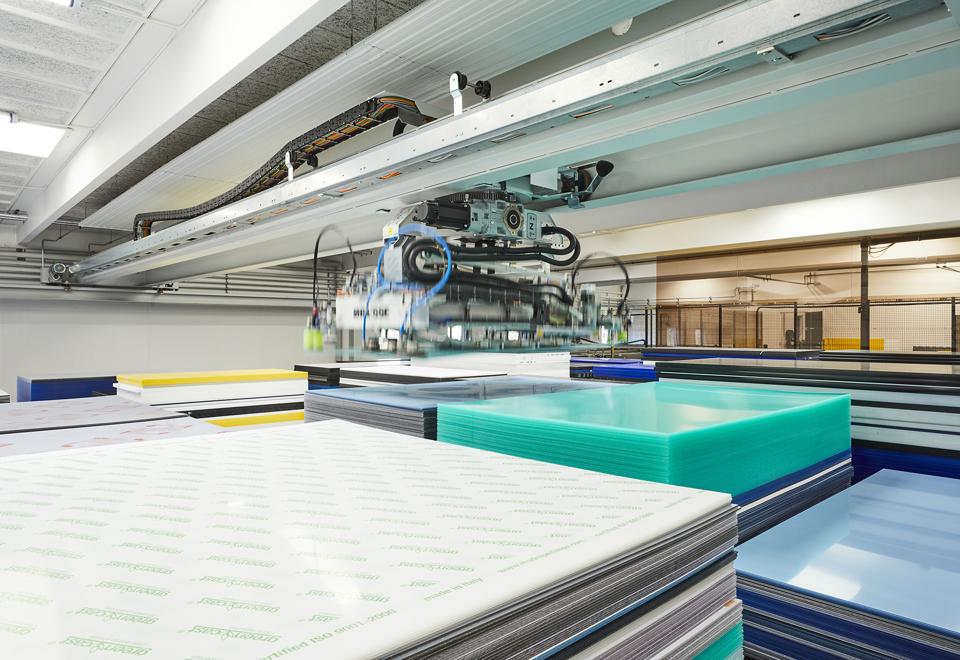

At Induflex, we specialize in providing plastic solutions for wind energy applications. These include cable management systems, protective housings, turbine components and gearboxes.

The ability of technical plastic to withstand high mechanical stress and extreme temperatures makes it an ideal material for such critical components.

Questions and Answers

-

At Induflex, we can achieve very tight tolerances in plastic.

When you order a plastic component from us, it adheres to the Danish Standard ISO 2768-1 (medium) by default. We measure tolerances at room temperature, around 21°C.

Of course, we can agree on different tolerances if you prefer.

-

Plastic is a more dynamic material than metal and steel, which means there are certain factors you need to consider.

You can read more about this in this article, where we have gathered 10 things to consider when designing with technical plastics.