FAQ

-

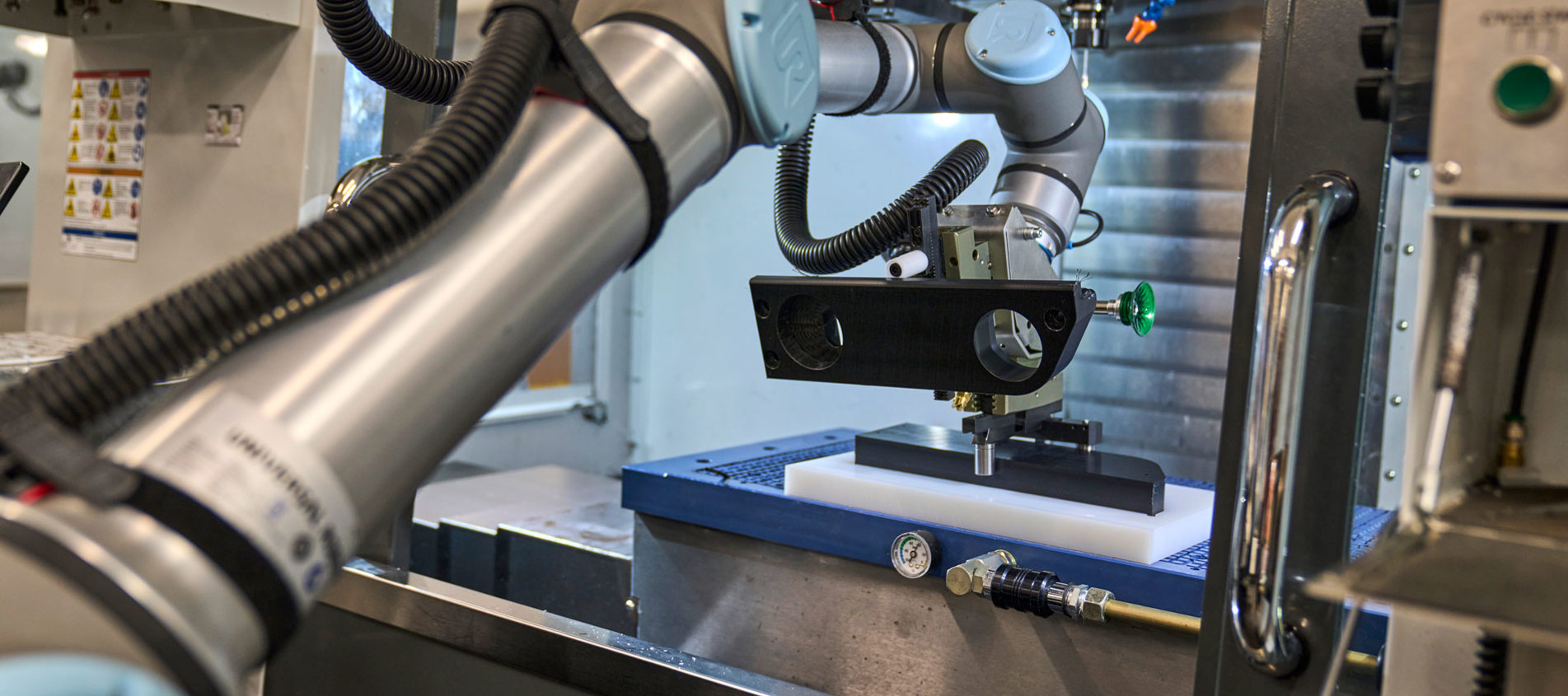

Whether you need one machine part or 1,000, we can produce it for you.

-

You can definitely save money if you order more machine parts. The setup costs are lower when the production is set up for mass production.

-

If you would like to receive a non-binding quote or place an order, simply send an email to induflex@induflex.dk.

Please attach a drawing of your item in STEP format, along with a PDF if possible.

You are also welcome to call us at +45 9837 1988 or fill out the contact form below, and we will ensure that the right employee contacts you.

Our materials

To ensure the best quality for you, we are working with the leading European suppliers of plastics materials. This also allows us to produce your prototypes and solutions fast.

Conversion to plastic

Did you know that plastic can be a beneficial replacement for materials like wood, steel, and metal? That's why plastic is used for machine parts, wear components, and much more to optimize projects with its numerous strong properties.