Questions and answers

-

If you would like to receive a non-binding quote or place an order, simply send an email to induflex@induflex.dk.

Please attach a drawing of your item in either DXF or STEP format, and optionally a PDF.

You are also welcome to call us at 9837 1988 or fill out the contact form below – we will ensure that the right team member contacts you.

-

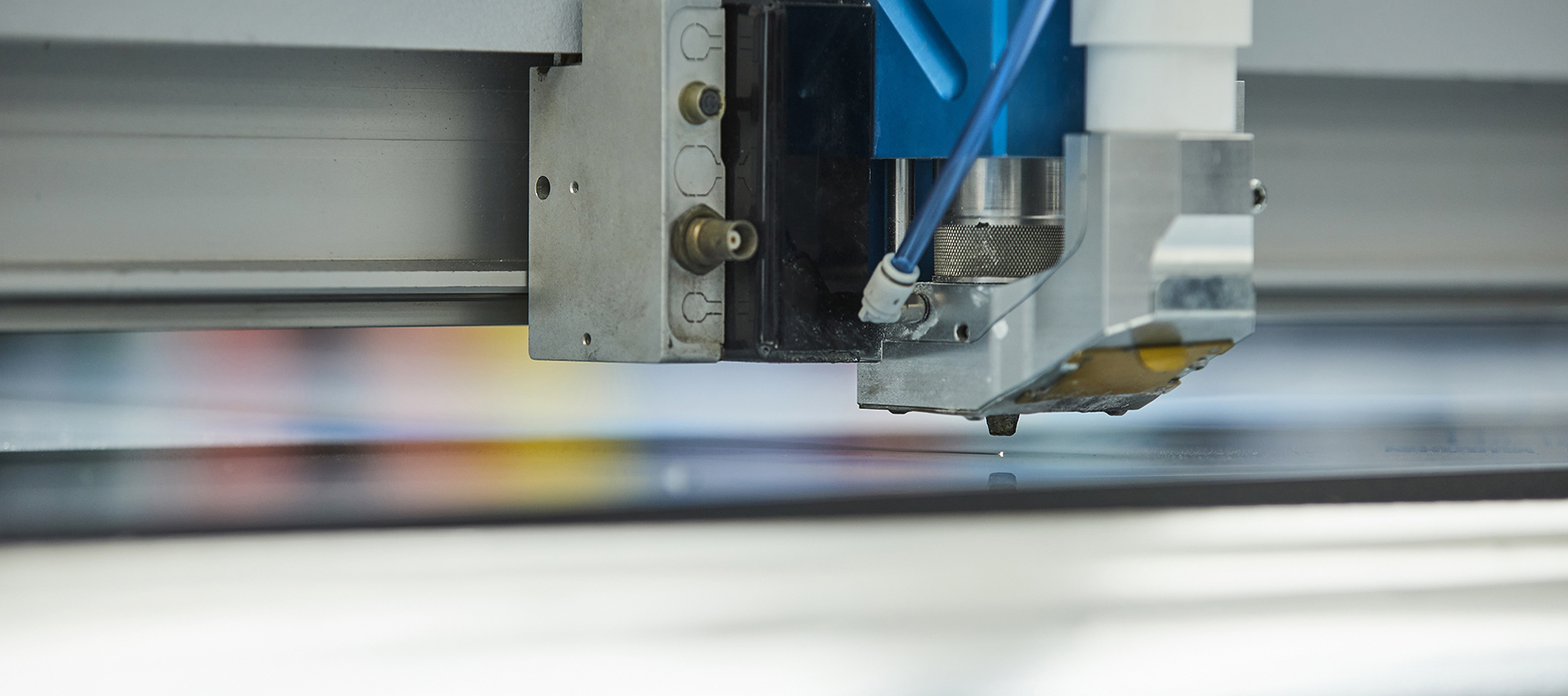

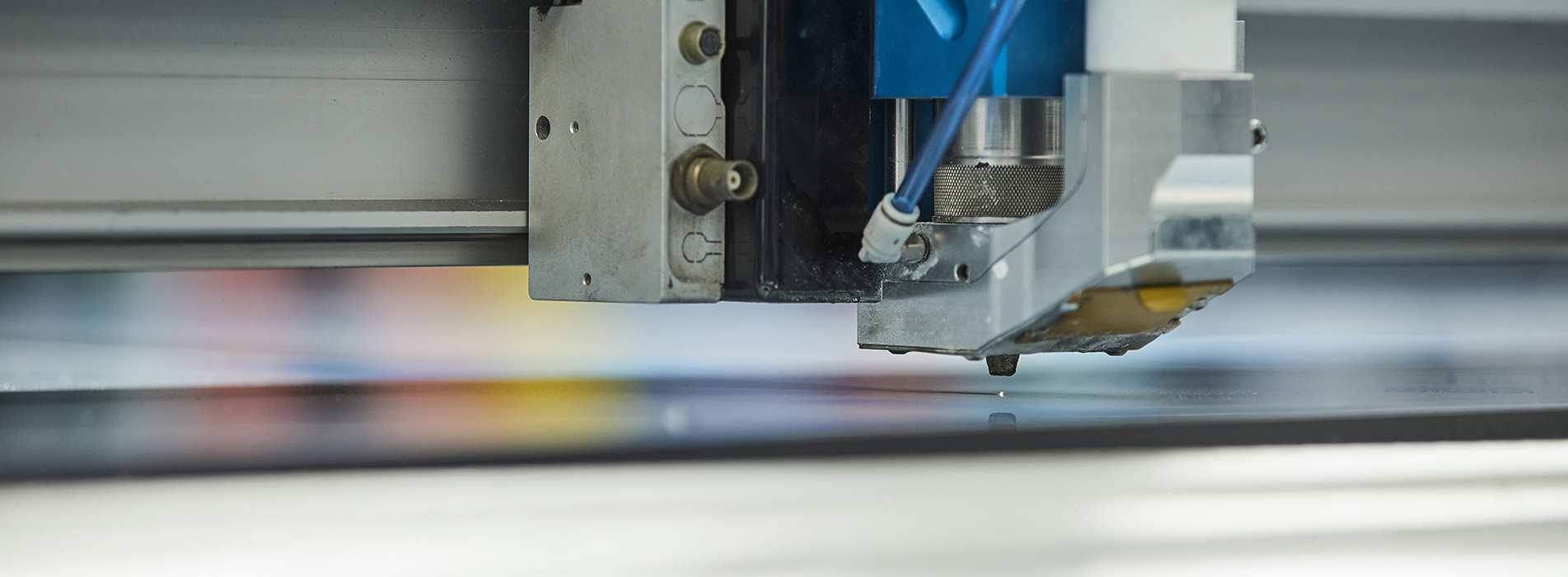

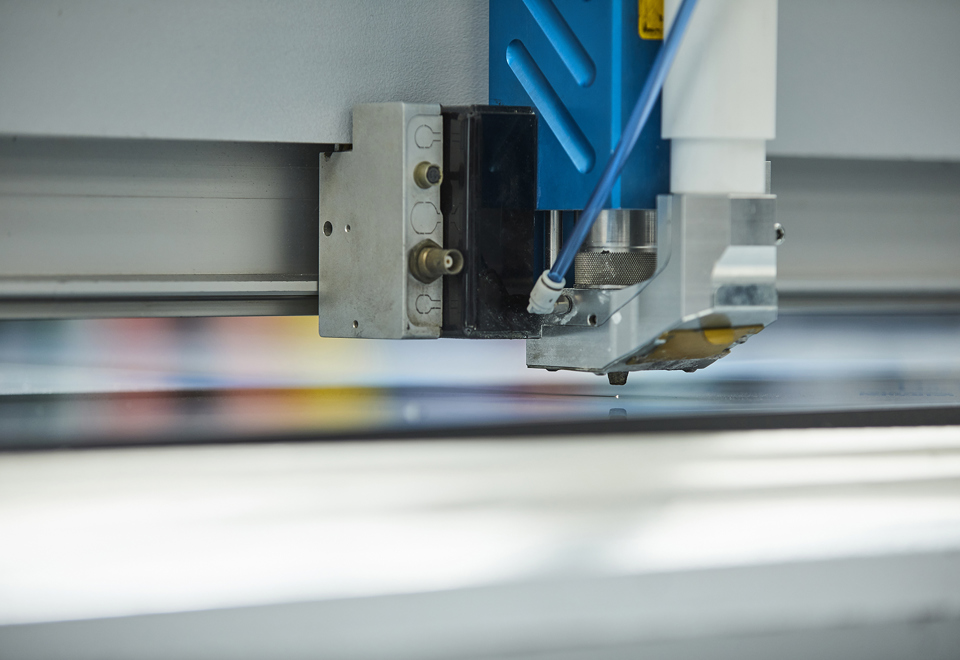

Our laser cutters can handle sheets up to a size of 3000 x 2200 x 20 mm.

If your product needs to be cut from a thicker sheet, our cutting plotters or CNC milling machines can easily take on the task.

-

At Induflex, we can produce even very tight tolerances in plastic.

When you order a plastic component from us, it will meet the Danish Standard ISO 2768-1 (medium) as standard. We measure tolerances at room temperature, around 21 °C.

Of course, we can agree on a different tolerance if you wish.

-

We primarily cut acrylic, ABS, PA (nylon), PETG, and PS on our laser cutters.

Certain materials are better suited for knife cutting on a plotter, which we also offer.

If you're unsure whether a specific material can be laser-cut, feel free to contact us for assistance.

-

We do not recommend laser cutting polycarbonate as it tends to burn.

Instead, we can mill your polycarbonate parts according to your specifications and measurements.

Please note that while laser cutting results in a clear edge, milling will leave the edge matte.

Apart from this difference, milling and laser cutting are quite comparable in terms of precision, and both methods provide highly accurate results.