Questions and answers

-

If you would like to receive a non-binding quote or place an order, simply send an email to induflex@induflex.dk.

Please attach a drawing of your item in either DXF or STEP format, or possibly a PDF.

You are also welcome to call us on +45 9837 1988 or fill in the contact form below – we will then ensure that the right employee contacts you.

We will send you a quote with a price before we start producing your order, unless we agree otherwise.

-

Standards serve as guidelines to ensure quality, safety and compatibility. They act as a common language between companies, consumers, etc., ensuring that the expectations of buyers and sellers are aligned.

The most commonly applicable standards for plastics are RoHS2, REACH and UL 94.

RoHS2 is a standard that concerns restrictions on the use of hazardous substances in electrical and electronic equipment.

The REACH Regulation is a chemical legislation in the EU that aims to ensure that chemicals are used safely and thus protect human health and the environment. The EU's chemical agency, ECHA, receives registrations and assesses whether they comply with the relevant legislation.

The UL94 standard is a classification of flame-resistant plastics. The standard classifies materials according to flammability into six groups.

In addition, there are a number of standards within various industries, including:

- EMC (Electromagnetic Compatibility)

- Automotive components

- ESD (Electrostatic Discharge)

- MT (Medical Technology)

At Induflex, we comply with all of the above standards.

We also process and sell food-approved materials and are therefore registered with and inspected by the Danish Veterinary and Food Administration, where we have an elite smiley in food contact materials (FKM).

-

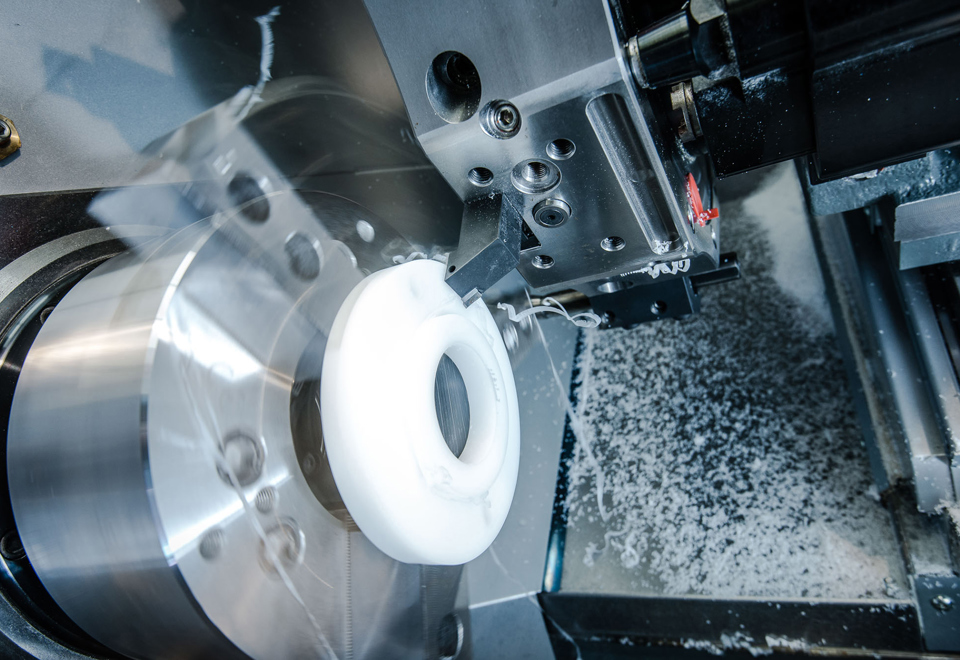

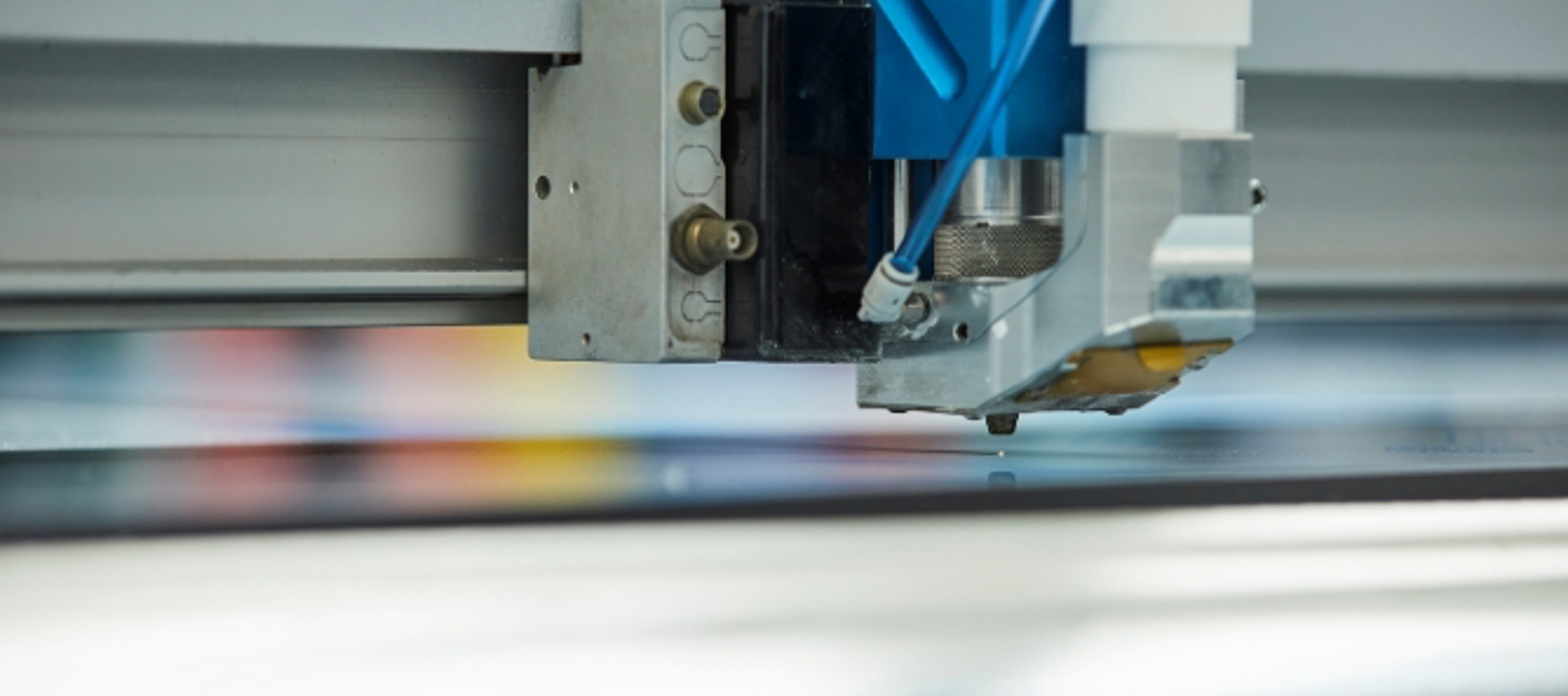

As a rule of thumb, we can produce items ranging in size from several metres down to millimetres.

However, this depends on the tolerances you require, the shape of the item and whether, for example, holes need to be drilled in the item, etc.

If you are unsure whether we can manufacture your item, please do not hesitate to contact us.

-

At Induflex, we can produce even very narrow tolerances in plastic.

When you order a plastic item from us, it complies with Danish Standard ISO 2768-1 (medium) as standard. We measure tolerances at room temperature, around 21 °C.

We can, of course, agree on a different tolerance if you wish.