Danfotech says

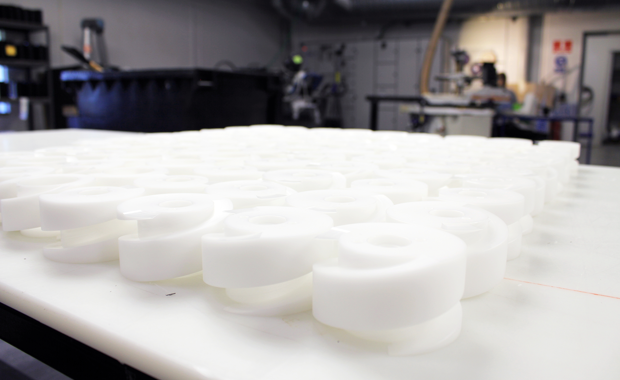

"We have worked with Induflex for several years, and we are very satisfied with the collaboration.

It is important to us that our subcontractors are reliable and fixable, as the plastic components are part of the ongoing production of our customised machines.

Although all the machine parts we order from Induflex are unique, we can always expect delivery of the right quality at the right time, with parts that meet our requirements for surfaces and tolerances."

Bettina Elbro, Purchasing Assistant at Danfotech Middleby Denmark.

Cases