At the intersection of innovation and cost-effectiveness, Cold Jet and Induflex have forged a dynamic partnership based on solid professional sparring and swift action.

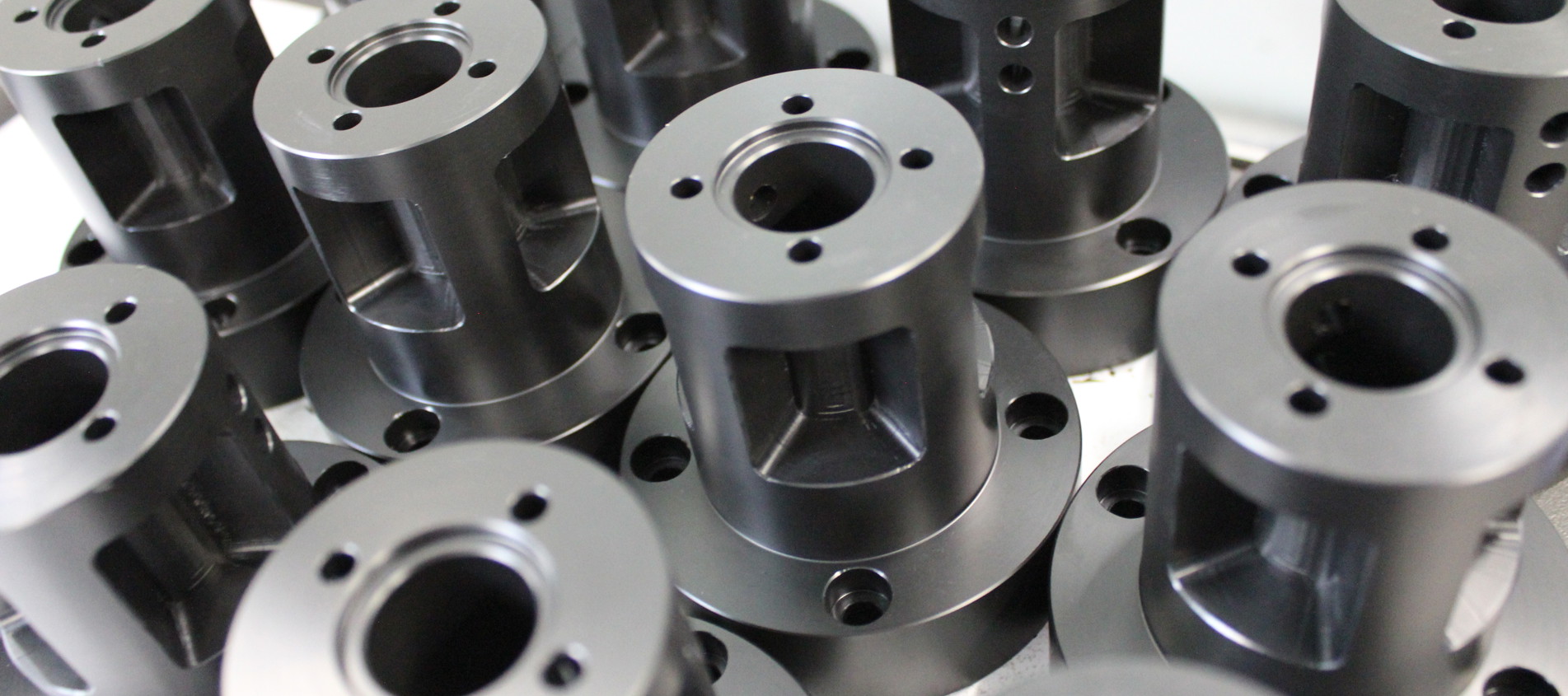

Cold Jet manufactures dry ice machines for cooling within the medical and food industriesm as well as dry ice machines for cleaning and surface treatment. When the need arose for POM components for a large-scale project, the buyer turned to their well-known collaboration partner, Induflex - a reliable specialist in the machining of plastic components.